Servo Puller-Cutter

Available Options:

- Pneumatic feed belt actuation

- Belt gap indicator

- Alternate belt widths and contact lengths

- Fully guarded puller assembly

- Servo motor upgrades for increased cutting torque

- Blade lubrication system

- Cutter head on X-Axis slide assembly

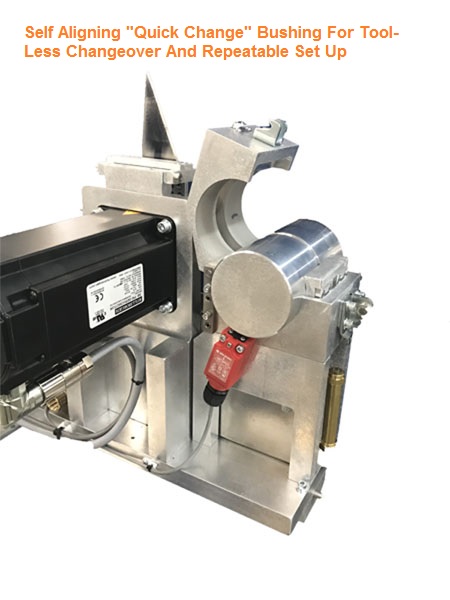

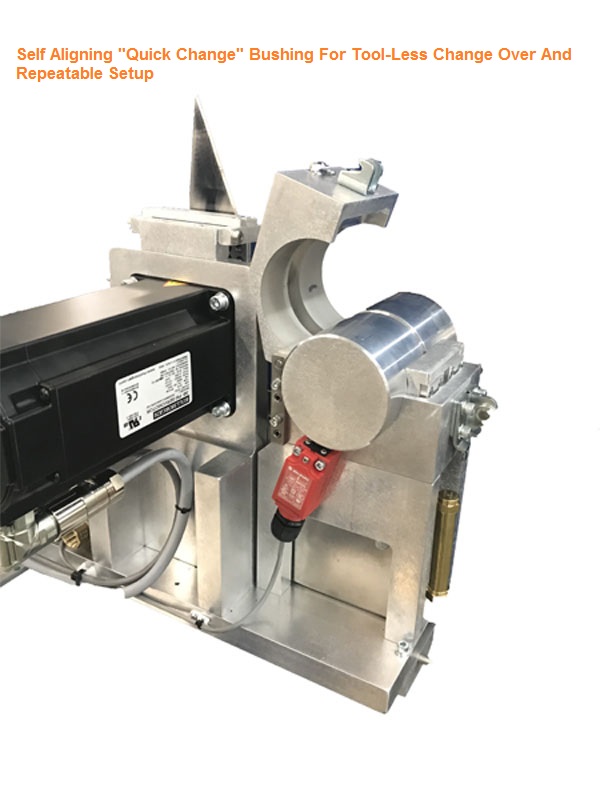

- Increased diameter self-aligning quick change bushings

ESI's servo puller-cutters are designed to meet a wide range of in-line flycutting of plastic and rubber tubings and profiles. Precision in-line cutting of extruded profiles and tubing requires the extrudate to be presented to the cutter at a consistent rate. ESI puller with integrated servo cutter unit offers a cut length accuracy of +/- .030" with an on-demand 400 cuts-per-minute capability. Units are available with larger servomotors for increased cutting torque, cutter head slide adjustments, larger diameter bushings, blade lubrication and fully caged puller assemblies.

Standard Features:

- 3" wide x 18" belt puller; timing belts driven via right angle gearboxes with vertical shaft; shaft driven via variable speed, AC inverter duty motor

- 80 In-Lb brushless servo cutter motor

- Unique Self-Aligning ‘Quick change’ bushing assembly (No tools required for bushing changeover)

- One-piece 3 ½” OD cutter bushing design

- Direct coupled cutter motor & blade holder – no belts or clutches

- On-Demand mode of up to 400 cuts-per-minute

- +/- .030” cut length accuracy capability (exclusive of product slippage, bow, curvature and shrinkage)

- Cutter guard electrically interlocked

- Puller assembly locally guarded