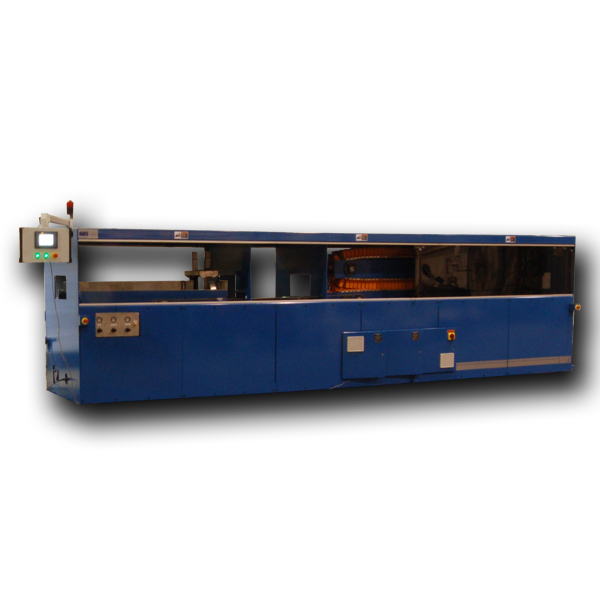

Performer Puller-Saw Combination

Available Options:

- Pneumatic belt actuation

- Quick Change cleats

- Independently driven puller belts/cleats

- Color touch Screen controls

- Servo controlled table motion

- Closed loop AC or Servo driven puller

- Smoked Lexan enclosure

- Integrated vacuum/dust control

- Automatic lubrication system

- Integrated surface finishing or film application

- Dual strand configurations

ESI Performer Series Puller-Saw Combinations provide an innovative, streamlined alternative to traditional extrusion line layouts. Combining two critical components of the extrusion line into a common platform and control package, enhances operator efficiency, conserves valuable floor space and insures proper machine alignment.

Performer PPS combinations are designed to provide smooth, consistent pull force while producing repeatable, finished cut-to-length parts at the end of the extrusion line. Performer PPS combinations are available with both cleated and smooth belt pullers in a variety of widths and contact lengths and with numerous drive choices. Saw table motion is synchronized using ESI's Posi-Lock speed control or via our optional ASC servo control package. Up-Cut and/or down cut saw motions are available. All ESI saws are equipped with AC inverter saw motors providing adjustable blade speed control and dynamic braking of the saw motor in power down or E-stop conditions. Full safety cages or optional sliding Lexan doors surround the puller and the saw compartments and all doors are electrically interlocked for safety.

Performer PPS combination units can also be configured with integrated embossing units or protective film applicators further streamlining the extrusion line layout. Used in combination with Performer PCT vacuum calibration tables, ESI's Performer Series provides a robust, flexible, state of the art platform in a modular extrusion line layout, designed to facilitate easier line string-up and operation, enhance operator efficiency and maximize available floor space.

Standard Features:

- Heavy duty construction

- Integrated puller and saw

- Puller Speed regulation +/- 0.5%

- Adjustable entry guide rollers

- AC inverter duty saw motor

- Adjustable blade RPM/dynamic braking

- Fully enclosed puller and saw enclosure

- Saw table mounted on heavy duty linear rails with sealed bearings

- Numerous puller and saw sizes