Conveyorized Spray Tank

Available Options:

- Closed loop water circulation system

- Shell & Tube heat exchanger

- Super Quench cooling

- Upgraded drive controls

- Non-contact sonic dancer control

- Geared lifter system to allow vertical adjustment of tank height

- Self-Contained blow-off system

- Single or Dual bag filtration system

- Custom lengths and cross sections

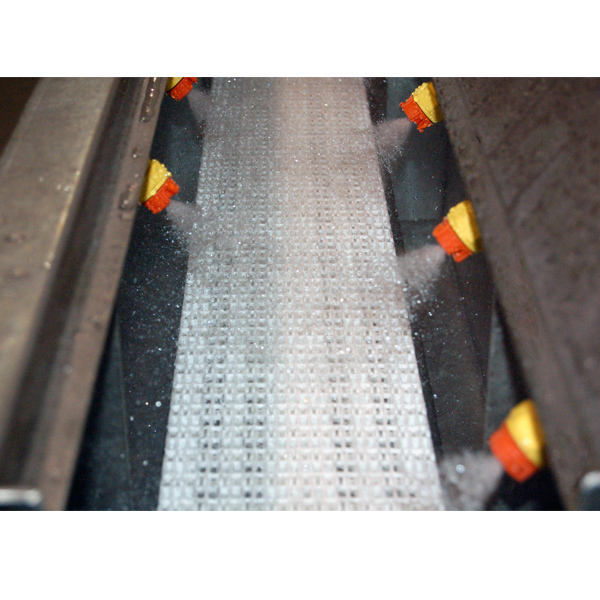

ESI's conveyorized spray tanks are designed to 'carry' your product downstream, with a low tension 'pull' while providing high efficiency, spray water cooling. Smooth belts are recommended for applications where product marking may be a problem. Open mesh systems are recommended for most efficient cooling.

Standard Features:

- A continuous smooth mesh (plastic or stainless steel) conveyor runs full length of the tank on a stainless slide

- Conveyor is driven by a variable speed AC or DC motor and drive

- Conveyor speed is controlled using a potentiometer mounted on operator panel

- Two, full length, high efficiency spray manifolds are mounted at upper corners of the tank, above the conveyor. With mesh systems spray manifolds are also mounted to spray through the belt.

- Stainless steel tank construction

- Stainless steel guide roller assemblies (vertical and horizontal); mounted at entry and exit ends

- Top mounted stainless steel lids

- Base tank system designed to utilize the customer’s water supply for continuous water circulation, includes supply inlets and drains

- Baffled air blow-off compartment, incorporating a flex-nozzle assembly with a fitting ready for customer connection to air supply