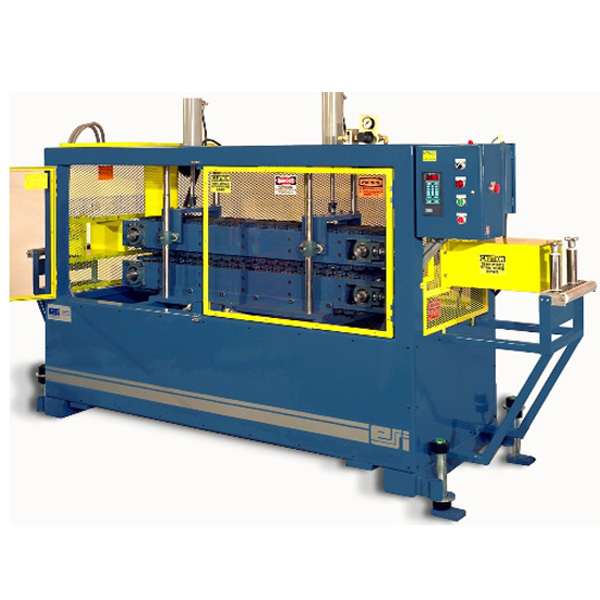

Cleated Belt Puller

Available Options:

- Flux vector drive with encoder feedback

- DC Drive including digital controller and display

- Quick change cleats

- Separate motors for upper and lower cleats, both driven by a common drive

ESI Cleated Pullers incorporate high traction, low wear, reinforced cleats for the downstream conveying of extrudate where large pulling force is required. Cleated Pullers are provided with a unique "floating" upper carriage that allows irregular shaped extrudate to pass through without interference as well as other options. Standard sizes include 6" to 12" wide cleats with 36" to 60" long traction lengths, but we have supplied cleated pullers in widths of up to 48” and lengths of up to 14’ with custom specifications as well.

Standard Features:

- Cleated chains are fitted with set of long wearing cleats

- Designed with heavy duty four-post frame assembly with bearing blocks and steel ‘H’ frame support plates between posts

- Pneumatic feed belt actuation of upper belt assembly; bottom belt is fixed

- Pivoting, self adjusting upper belt assembly

- Belts are driven via common variable speed, AC inverter duty motor thru a heavy duty double sprocket and chain assembly which includes a self adjusting tensioner

- Motor controller is a variable speed, sensorless AC vector drive

- Operator controls include: power On/Off, manual potentiometer, digital display of puller speed and ‘E' stop

- Full safety cage with keyed interlocks for safety