Spray Tanks

Available Options:

- Closed loop water circulation system

- Shell & Tube heat exchanger

- Super Quench cooling

- Geared lifter system to allow vertical adjustment of tank height

- Self-Contained blow-off system

- Single or Dual bag filtration system

- Two-up design

- Custom lengths and cross sections

ESI high efficiency spray cooling tanks are available in a wide variety of standard cross sections and lengths in either one-up or two-up designs.

Stainless steel support rollers are mounted within the tank. Spray manifolds surround the extrudate and stainless steel centrifugal pumps provide a highly atomized spray pattern that ensures maximum heat removal by evaporative cooling.

Standard Features:

- Non-driven support rollers

- High efficiency quad spray manifolds, full length

- Stainless steel tank construction

- Stainless steel guide roller assemblies (vertical and horizontal); mounted at entry and exit ends

- Top mounted stainless steel lids

- Base tank system designed to utilize the customer’s water supply for continuous water circulation, includes supply inlets and drains

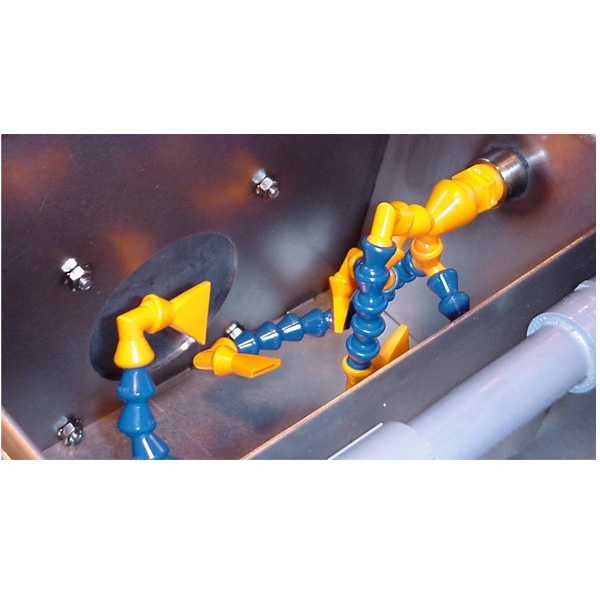

- Baffled air blow-off compartment, incorporating a flex-nozzle assembly with a fitting ready for customer connection to air supply