Triple Servo Puller-Cutter

Available Options:

- Pneumatic feed belt actuation

- Belt gap indicator

- Alternate puller widths and contact lengths

- Fully guarded puller assembly

- Blade lubrication system

- Cutter head on X-Axis slide assembly

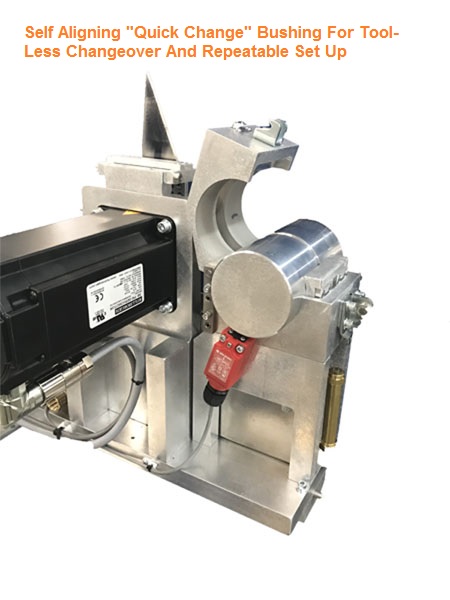

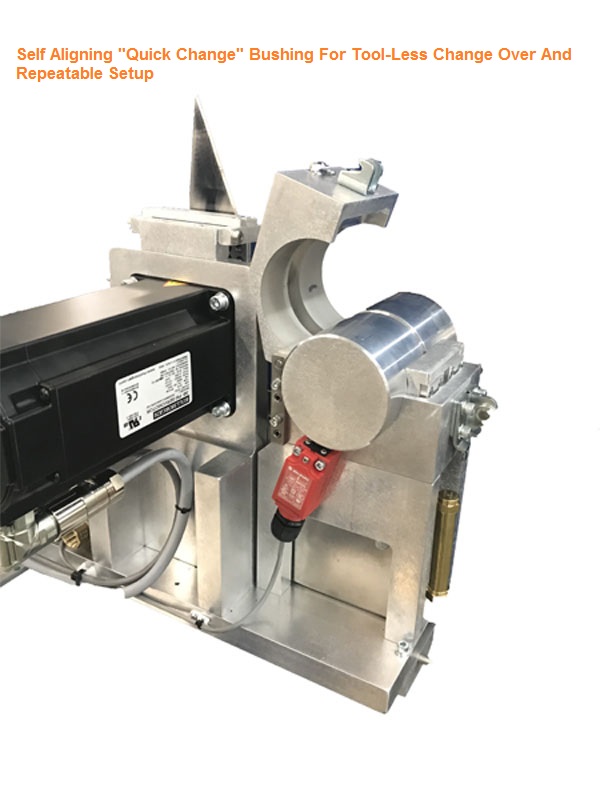

- Increased diameter self-aligning quick change bushings

- Corrugated tube and cuff cutting

- External cut trigger tracking and length adjustment

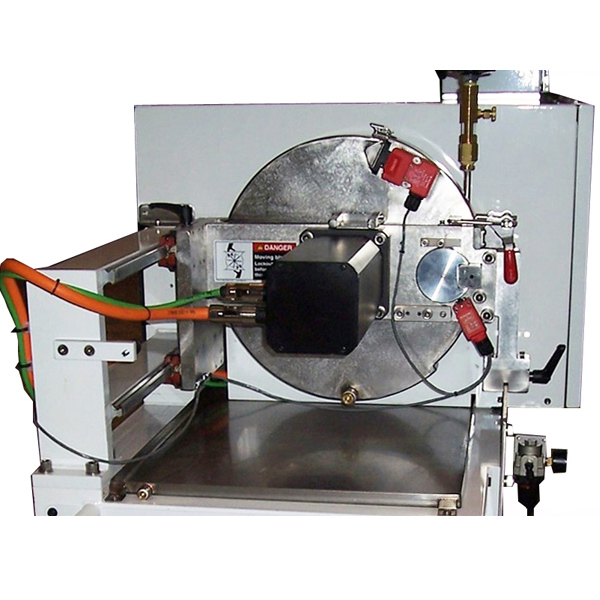

Combines industry leading cut length accuracy with a robust machine platform providing unmatched reliability and precision for inline and offline cut to length applications. Our cutting-edge motion controls package is spearheaded by independent directly driven servomotors and intelligent drives for each puller belt and for the fly knife cutter. This puller-cutter has been used extensively for applications which demand critical cut length tolerances with coordinated automation such as: automatically adjusting individual cut lengths in response to feature locations sensed by vision systems, locating multiple cuffs in corrugated tubing, trimming cuff length while tracking multiple different parts, and separating into different bins off the packing conveyor.

Standard Features:

- 3“ wide x 18“ belt pullers; each belt driven via individual brushless servo motor with planetary gearbox and controlled with individual intelligent servo drive

- 130 In-Lb brushless servo cutter motor

- Unique Self-Aligning ‘Quick change’ bushing assembly (No tools required for bushing changeover)

- One-piece 3 ½” OD cutter bushing design

- Direct coupled cutter motor & blade holder – no belts or clutches

- System cycle rate is limited to 750 CPM in ‘On-Demand’ mode; 2000 CPM in ‘Camming’ mode and up to 3000 CPM in ‘Continuous’ mode

- +/- .005” cut length accuracy capability (exclusive of product slippage, bow, curvature and shrinkage)

- Cutter guard electrically interlocked

- Puller assembly is locally guarded

- Three axis solid state triple servo programmable controller