Dual-Strand Boosting Saw with ASC (Advanced Servo Control)

Available Options:

- Kerf & Dust collection system

- Various blade diameters

- Various motor sizes

- Air boost in lieu of servo

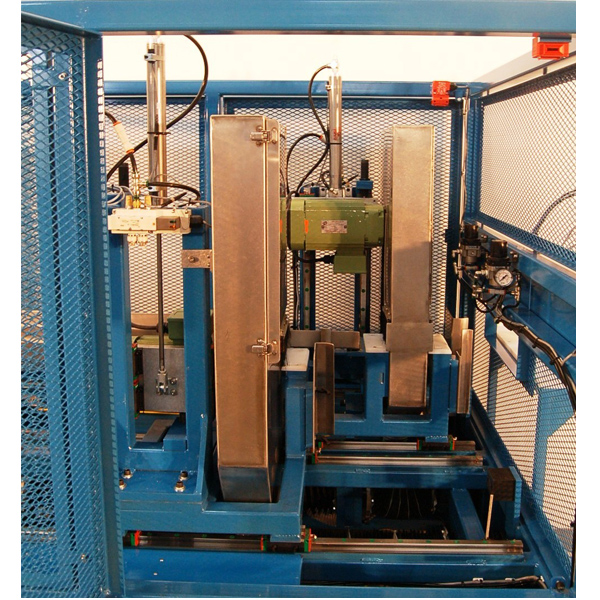

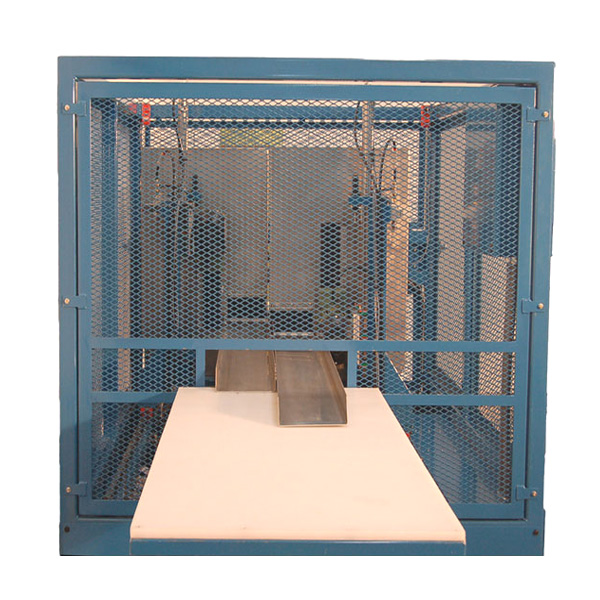

ESI's ASC servo boosting saws are also available in Dual-Up configurations. The dual-up saw system consists of two (2) independently controlled servo boosting saw carriages on a common frame where the action of each saw table is controlled by a single, solid-state programmable motion controller. The controller processes the signals from the high-resolution line encoders, synchronizes the cut cycle, and controls the motion of the saw and traveling table. A color touchscreen is supplied for control inputs and status.

Standard Features:

- The saw system consists of two (2) independently controlled servo boosting saw carriages on a common frame

- Two blades located side by side at set center to center distances to accommodate the customers 2-up extrusion

- Saw blades are driven by AC motors (saw blade assemblies are 'down cut' design)

- Each saw motor drive system includes an AC Inverter that provides dynamic braking to saw blade motor (stops motor when interlocked door is opened for added safety); also provides variable speed control of the saw motor for various cutting conditions

- The blade assemblies are brought into contact with the extrudate by means of pneumatic cylinders; speed is adjustable to allow for different cutting conditions

- The moving saw tables, mounted on heavy duty linear guide rails, are driven by a servo ball screws

- Each saw carriage movement is matched to line speed by high-resolution line encoders

- The action of each saw a single, solid-state, programmable motion controller controls table. The controller synchronizes the motion of the saw carriages to the extrudate

- A color touchscreen is supplied for control inputs and status.

- An expanded metal safety cage surrounds the entire assembly with keyed interlocks for safety