Product Line: Plastic

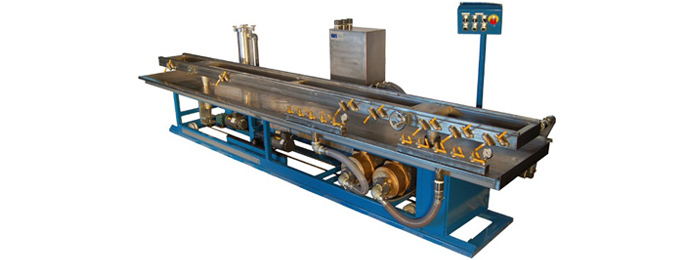

Show / Hide DescriptionFlood Tanks

ESI's flood tanks are designed for immersion cooling of rubber and plastic tubing and profiles and are available in a wide variety of standard cross sections and lengths.

HD-Series Belt Puller

ESI HD series pullers are designed to deliver maximum pull force and speed consistency where a cleated belt puller may not be suitable. With 6" and 12" belt width and 36", 48" and 60" contact length these chain driven pullers are suitable where large pulling force and very robust construction are required. Various belt materials are available for maximum grip on your product.

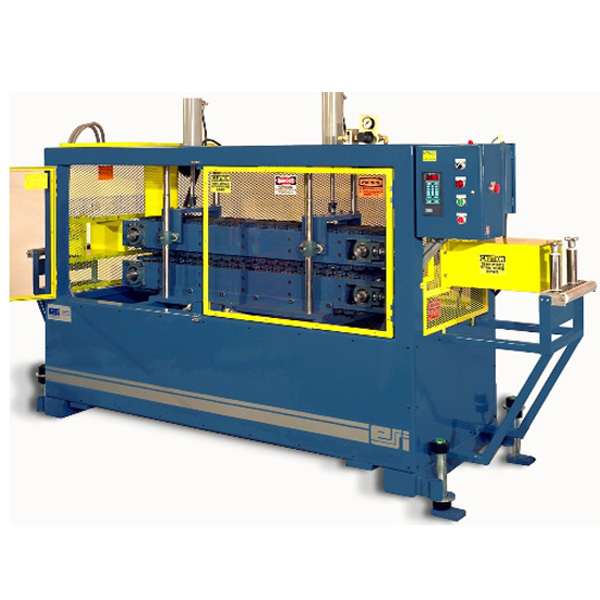

Accusaw Series

ESI's unique Accusaw series of stop/go saws have a long history of providing precision, in-line, cut-to-length results to the extruders of flexible rubber and plastic profiles and hose (both reinforced and non reinforced). The Accusaw features a servo driven smooth belt feeder and fiber optic length control that effectively eliminates slippage. The servo driven belt feeder precisely advances the extrudate through the saw until shortly before the desired cut length is reached. The feeder is then slowed until the fiber optic sensor is triggered, at which point the feeder is stopped, with no interruption to the extrusion process, and the cut is performed.

Servo Puller-Cutter

ESI's servo puller-cutters are designed to meet a wide range of in-line flycutting of plastic and rubber tubings and profiles. Precision in-line cutting of extruded profiles and tubing requires the extrudate to be presented to the cutter at a consistent rate. ESI puller with integrated servo cutter unit offers a cut length accuracy of +/- .030" with an on-demand 400 cuts-per-minute capability. Units are available with larger servomotors for increased cutting torque, cutter head slide adjustments, larger diameter bushings, blade lubrication and fully caged puller assemblies.

Vacuum Calibration Table

ESI's Vacuum Tables are designed for the processing of plastic profiles in a variety of rigid materials. Tables can be supplied in a variety of widths and lengths with different manifold and cooling options. Standard features include high performance liquid seal vacuum pumps for accurate and consistent vacuum control and multi-directional tank movement with hand wheel adjustment.

ESI tables are available with optional features such as closed loop circulation systems with high ...

Cleated Belt Puller

ESI Cleated Pullers incorporate high traction, low wear, reinforced cleats for the downstream conveying of extrudate where large pulling force is required. Cleated Pullers are provided with a unique "floating" upper carriage that allows irregular shaped extrudate to pass through without interference as well as other options. Standard sizes include 6" to 12" wide cleats with 36" to 60" long traction lengths, but we have supplied cleated pullers in widths of up to 48” and lengths of up to 14’ with custom specifications as well.

Full Vacuum Sizing Tanks

ESI's Full Vacuum Sizing Tanks are designed for the processing of tubing and small pipe in a variety of rigid and flexible materials. A variety of different cross sections and tank lengths are available. All tanks are manufactured of heavy gauge stainless steel and incorporate non-corrosive internal components. Standard features include high performance liquid seal vacuum pumps or venturi style injectors for accurate and consistent vacuum control, as well as multi-compartment designs, individual vacuum and volume adjustment, clear tempered glass lids with self adjusting hinge assemblies, large overflow basins and multi-directional tank movement ...

Cross-Cut Saw

For wide, flexible or rigid profiles choose ESI's Cross-Cut saw. Our cross-cut saws incorporate a moving saw carriage mounted on lineal rails. Carriage movement can be controlled by utilizing a high resolution encoder in conjunction with a servo motor and precision ball screw assembly or using an optional pneumatic clamp and air assist for less precise applications. The cross-cut traverse is available with either air control or motor for speed control. ESI also provides numerous choices in blade diameter, saw motor sizes, saw platform and control packages.

Multi-Pass Cooling Tank

When you are limited on floor space for your cooling needs, just look to ESI's Multi-Pass cooling tanks to solve your problem. With our Multi-Pass cooling tank, your flexible plastic or rubber profile can be wrapped several times around our custom capstan rollers to eliminate the need for longer or multiple spray tanks.

Let-Offs

Powered Let-Offs are designed to unwind profile from coiled reels. They are typically utilized on crosshead extrusion lines and can be used for letting off metal reinforcement (e.g. automotive seal lines) or extruded tubes with or without reinforcement (e.g. hose lines). Let-offs are often supplied in conjunction with accumulators to ensure continuous supply of material to the extrusion line. Let-offs can also be used for transfer of bulk coiled extrudate to smaller consumer sized packages. Let-offs are typically dancer controlled to adjust reel speed as effective reel diameter changes and can be designed as single station or dual station. Machines are designed for a ...