Product Line: Plastic

Show / Hide DescriptionTriple Servo Puller-Cutter

Combines industry leading cut length accuracy with a robust machine platform providing unmatched reliability and precision for inline and offline cut to length applications. Our cutting-edge motion controls package is spearheaded by independent directly driven servomotors and intelligent drives for each puller belt and for the fly knife cutter. This puller- cutter has been used extensively for applications which demand critical cut length tolerances with coordinated automation such as: automatically adjusting individual cut lengths in response to feature locations sensed by vision systems, locating multiple cuffs in corrugated tubing, trimming cuff length while tracking multiple different parts, and separating into different bins off the packing conveyor.

Combination Vacuum Sizing Tanks

ESI combination vacuum sizing tanks offer the ultimate in sizing and cooling flexibility to accommodate the varying sizing needs associated with profile vacuum calibration and atmospheric sizing of tubes and hollows. Combination tanks provide the ability to utilize full vacuum and/or vacuum calibration sizing on a common machine platform.

MD-Series Belt Puller

ESI MD series pullers are suitable for vast array of extrusion processes. MD series pullers deliver consistent pulling speeds and reliability, critical for accurate extrusion sizing. MD series pullers are available in standard widths of 3" and 5", 6” with standard traction lengths ranging from 24" to 36".

Air Boosting Saw

ESI air boosting (traveling) saws, for rigid extrudates, incorporate moving saw tables mounted on linear rails. Saw table is matched to line speed through a clamping cylinder and air cylinder assist. ESI also provides numerous choices in blade diameter, saw motor sizes, saw platform and control packages.

Accufly

ESI's Accufly® in-line cutting system offers innovative technology with high accuracy cutting by incorporating a servo driven stop/go feeder with fiber optics for cut-to-length signaling. Length is set by adjusting the fiber optic bridge assembly, or utilizing the servo feedback from the feeder motor. Just prior to the set length being reached, the feeder belts ramp down to ensure proper cut length positioning without overshoot. When the fiber optic beam is broken, the feeder belts stop and the servo driven flyknife is cycled, resulting in a square cut and high accuracy cut length. Because the feeder is maintaining a loop ahead of the Accufly, the product is fed without ...

Cut-and-Transfer coiler

ESI Cut-and-transfer coilers automatically cut the extrudate to length, index coiling stations and start the next coil without operator intervention. This can greatly reduce labor by allowing the operator to be assigned additional tasks, instead of waiting for the reel to complete. On high speed extrusion lines or lines which run short length coils it is often necessary to allocate an operator exclusively to the coiling station to change reels. The time taken to manually change reels often results in a significant length of extrudate being accumulated during the changeover causing extrudate to pile up on the floor and the operator to run the coiler at a very high speed to catch up.

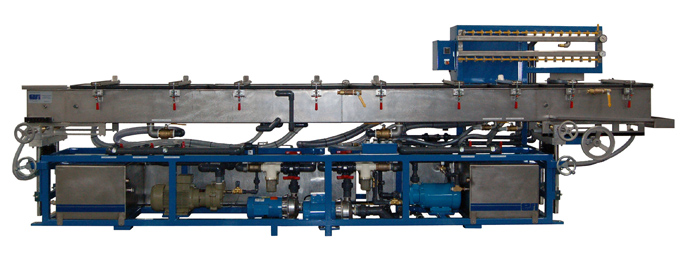

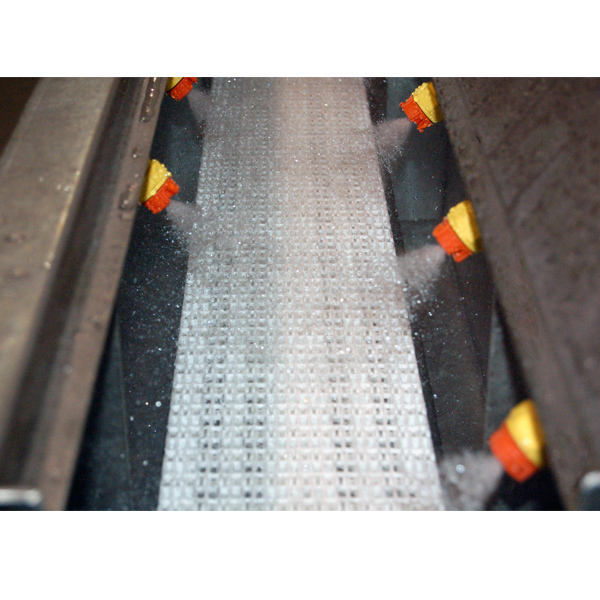

Conveyorized Spray Tank

ESI's conveyorized spray tanks are designed to 'carry' your product downstream, with a low tension 'pull' while providing high efficiency, spray water cooling. Smooth belts are recommended for applications where product marking may be a problem. Open mesh systems are recommended for most efficient cooling.

ASC (Advanced Servo Control) Puller-Cutter

ESI's dual servo puller-cutters are designed to meet a wide range of in-line flycutting of plastic and rubber tubings and profiles. Precision in-line cutting of extruded profiles and tubing requires the extrudate to be presented to the cutter at a consistent rate. Our dual servo puller-cutter unit includes a fully programmable motion controller, color touchscreen, servomotors for both puller & cutter. System offers a cut length accuracy of +/- .010" with electronic camming of blade motion to achieve peak blade speed at any cut rate up to 1000 cuts per minute and a continuous cut mode of up to 1800 cuts-per-minute.

Performer PCT Vacuum Calibration Tables

ESI is pleased to announce the addition of the Performer Series vacuum calibration tables to our complete line of U.S. manufactured downstream extrusion processing equipment. The Performer PCT platform provides ultimate flexibility in vacuum sizing while maintaining precise vacuum level control and providing high efficiency cooling of extrudates through the use of optional table mounted tanks.

Airfly Cutter

The patented Airfly cutting head was designed as a simple, efficient cutting device with very few moving parts for low maintenance. The Airfly is an 'on-demand' pneumatically powered flyknife cutter can be furnished as a 'table top' unit with basic controls. It is powered by multiple stainless steel air cylinders, and does not require the use of an electric or vacuum/clutch brake, has no linings to wear or replace, needs no electric motors or over-excitation circuits, and operates without the need for timing drums and belts. The Airfly is available in a standard 3.5" bushing size.