Product Line: Plastic

Show / Hide DescriptionServo Press Accupunch

The Accupunch series machines provide precision fabrication functions such as punching, notching and complex end cuts of flexible and rigid plastic, rubber or composite profiles to finished part tolerances while still in the extrusion line. High torque servomotors actuating offset cranks are used for providing high speeds to the Servo Press Accupunch. Presses can be mounted in different planes to provide multi-axis fabrication.

Accupunch precision is achieved by incorporating a servo driven, stop/go feeder with fiber ...

Embossers

Use ESI's embossers to create patterns on your plastic or composite profiles. These machines are often utilized for embossing wood grain patterns on composite or foamed PVC decking profiles. Our heavy-duty, two-post assembly embossing stands can be custom designed to meet all your in-line or off-line processes to one, two or four surfaces of your profile. Options include driven or non-driven rolls, electrically or hot oil heated rolls, single strand or multi-strand designs, various width or diameter rolls, pre-heaters and automatic roll movement for ‘random’ patterns.

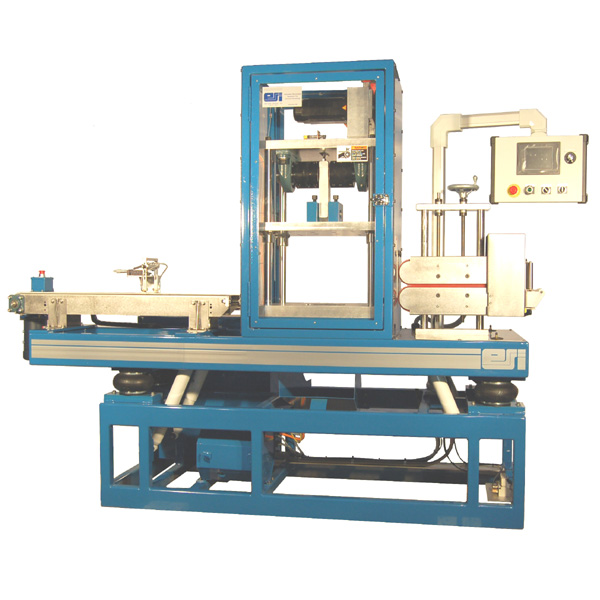

Air Press Accupunch

The Accupunch series machines provide precision fabrication functions such as punching, notching and complex end cuts of flexible and rigid plastic, rubber or composite profiles to finished part tolerances while still in the extrusion line. ESI has produced Air Press Accupunches for over 25 years. Large air bladders are used for providing high punch forces to the Air Press Accupunch. Presses can be mounted in different planes to provide multi-axis fabrication.

Accupunch precision is achieved by incorporating a servo driven, stop/go feeder with fiber ...

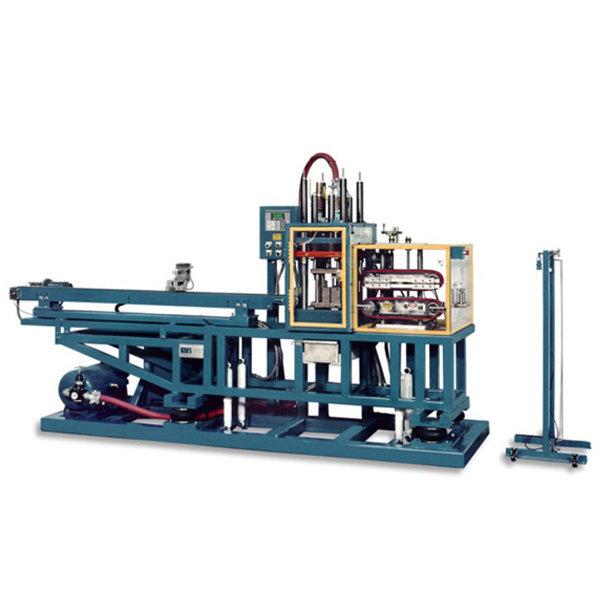

Boosting Punch with ASC (advanced servo control)

ESI’s ASC boosting punch is designed for fabricating profiles too rigid to stop with the Accupunch. The machine represents a combination of the press used on ESI’s top selling Accupunch and the controls utilized on ESI’s ASC boosting saw. The press is an air diaphragm type with up to 3” stroke and spring return. Standard press size is 20-1/2 x 15-1/2. A full safety cage surrounds the press and boosting mechanism. Support tables are mounted before and after press.

Custom In-line Fabrication

Since it’s inception in 1981, ESI has specialized in on-line fabrication. While the Accupunch series has been available since the early days, ESI is constantly evolving the capabilities of the series. ESI has supplied Accupunches with up to five fabrication presses (some equipped with programmable product features and often mounted in multiple planes), routing systems, drilling systems, sawing systems. ESI has also supplied many variations of boosting fabrication ...

SD-Series Belt Puller

ESI SD series pullers are a perfect choice for small profiles and tubing with lower pull force requirements as well as high-speed applications. Rubber coated timing belts are utilized providing "zero slip" with the drive pulleys. SD series offer adjustable belt height and are available with numerous belt materials, drive choices and speed ranges.

Servo Cutter

For higher performance cutting applications, our servo driven flycutters are available with a variety of cutting torques and speeds. Brushless servomotors, directly coupled to the machined blade holder, drive these cutters. Since no friction wear surfaces such as clutch or brake assemblies are utilized, continuous adjustment or replacement to insure accuracy is a thing of the past. The base servo control provides for 'on-demand' cutting with simple operation through the standard interface. ASC servo cutters are also available with automatic camming allowing non continuous flyknife motion up to 1000 cuts per minute and continuous cutting up to 1400 ...

Boosting Saw with ASC (Advanced Servo Control)

ESI servo boosting (traveling) saws, for rigid extrudates, incorporate moving saw tables mounted on linear rails. ESI servo boosting saws provide superior cut length accuracy control by utilizing high resolution encoders in conjunction with a servo-motor and precision ball screw assembly. ESI servo saws have proven to produce in-line cut length accuracy of +/- .020". Models are available in either single strand or dual up configurations. ESI also provides numerous choices in blade diameter, saw motor sizes, saw platform and control packages.

Coilers

ESI coilers are available in single or dual station designs. When two coiling stations are provided, operator switches stations when one reel is full while other station is coiling. Coilers can be supplied with traverse mechanisms for layering extrudate side by side on a wide reel or without traverse for strip winding applications. Mechanical traverses are driven by the main coiler drive and allow the operator to mechanically adjust the ratio on the traverse mechanism. Upgraded electronic traverses are also available which incorporate a separate drive motor, which is electronically ratioed to the main coiler drive. Coilers are supplied with dancer mechanisms ...

Spray Tanks

ESI high efficiency spray cooling tanks are available in a wide variety of standard cross sections and lengths in either one-up or two-up designs. Stainless steel support rollers are mounted within the tank. Spray manifolds surround the extrudate and stainless steel centrifugal pumps provide a highly atomized spray pattern that ensures maximum heat removal by evaporative cooling.