Product Line: Plastic Composite

Show / Hide DescriptionPerformer PCT Vacuum Calibration Tables

ESI is pleased to announce the addition of the Performer Series vacuum calibration tables to our complete line of U.S. manufactured downstream extrusion processing equipment. The Performer PCT platform provides ultimate flexibility in vacuum sizing while maintaining precise vacuum level control and providing high efficiency cooling of extrudates through the use of optional table mounted tanks.

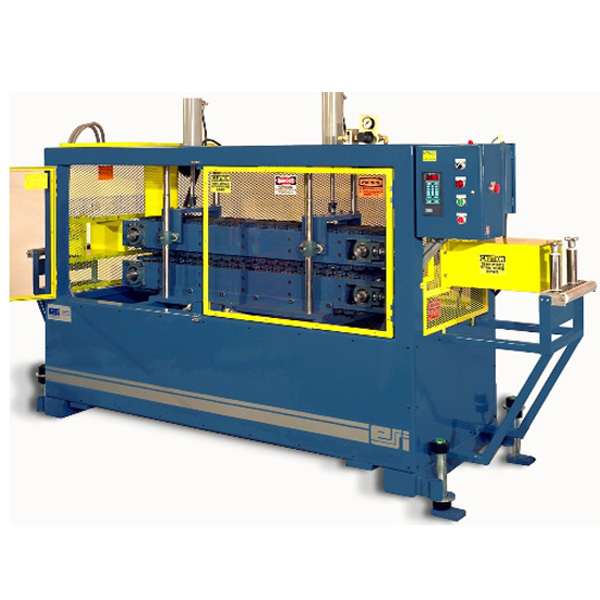

HD-Series Belt Puller

ESI HD series pullers are designed to deliver maximum pull force and speed consistency where a cleated belt puller may not be suitable. With 6" and 12" belt width and 36", 48" and 60" contact length these chain driven pullers are suitable where large pulling force and very robust construction are required. Various belt materials are available for maximum grip on your product.

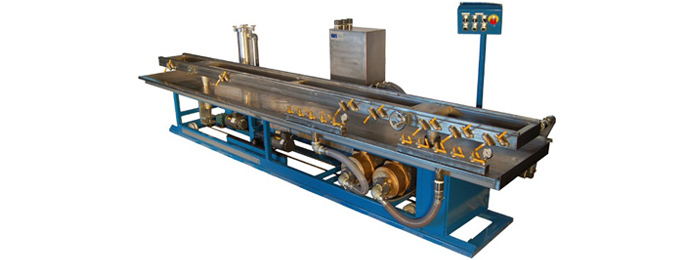

Vacuum Calibration Table

ESI's Vacuum Tables are designed for the processing of plastic profiles in a variety of rigid materials. Tables can be supplied in a variety of widths and lengths with different manifold and cooling options. Standard features include high performance liquid seal vacuum pumps for accurate and consistent vacuum control and multi-directional tank movement with hand wheel adjustment.

ESI tables are available with optional features such as closed loop circulation systems with high ...

Cleated Belt Puller

ESI Cleated Pullers incorporate high traction, low wear, reinforced cleats for the downstream conveying of extrudate where large pulling force is required. Cleated Pullers are provided with a unique "floating" upper carriage that allows irregular shaped extrudate to pass through without interference as well as other options. Standard sizes include 6" to 12" wide cleats with 36" to 60" long traction lengths, but we have supplied cleated pullers in widths of up to 48” and lengths of up to 14’ with custom specifications as well.

Cross-Cut Saw

For wide, flexible or rigid profiles choose ESI's Cross-Cut saw. Our cross-cut saws incorporate a moving saw carriage mounted on lineal rails. Carriage movement can be controlled by utilizing a high resolution encoder in conjunction with a servo motor and precision ball screw assembly or using an optional pneumatic clamp and air assist for less precise applications. The cross-cut traverse is available with either air control or motor for speed control. ESI also provides numerous choices in blade diameter, saw motor sizes, saw platform and control packages.

Vacuum Calibration Tanks

ESI's Vacuum Calibration Sizing Tanks are designed for the processing of plastic profiles in a variety of rigid and flexible materials. Tanks can be supplied in a variety of cross sections and lengths with different manifold and cooling options. ESI also offers hot water annealing of the front section to minimize bow in profiles with uneven thicknesses, allowing the product temperature to drop below the glass transition point before cooling with chilled water. This greatly reduces bow and camber on many profiles.

Performer Puller-Saw Combination

ESI Performer Series Puller-Saw Combinations provide an innovative, streamlined alternative to traditional extrusion line layouts. Combining two critical components of the extrusion line into a common platform and control package, enhances operator efficiency, conserves valuable floor space and insures proper machine alignment.

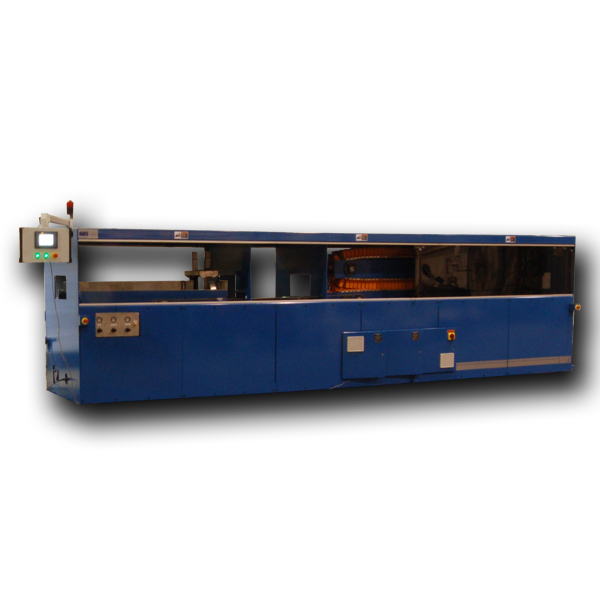

Dual-Strand Boosting Saw with ASC (Advanced Servo Control)

ESI's ASC servo boosting saws are also available in Dual-Up configurations. The dual-up saw system consists of two (2) independently controlled servo boosting saw carriages on a common frame where the action of each saw table is controlled by a single, solid-state programmable motion controller. The controller processes the signals from the high-resolution line encoders, synchronizes the cut cycle, and controls the motion of the saw and traveling table. A color touchscreen is supplied for control inputs and status.